Views: 0 Author: Site Editor Publish Time: 2026-01-19 Origin: Site

Have you ever been stuck in a bus with a malfunctioning air conditioner on a hot day? Not only does it make the ride uncomfortable for passengers, but it can also distract the driver, leading to potential safety risks. A well-maintained bus air conditioning system is crucial for ensuring a comfortable, cool, and safe environment on the road.

In this article, we’ll explore the most common problems bus air conditioners face and offer practical solutions to resolve them quickly. We’ll also highlight TCHAIN’s innovative products and services, designed to prevent these issues and promote proactive maintenance for smoother operations.

Bus air conditioners are robust systems, but they can experience problems over time due to factors such as lack of maintenance, wear and tear, and exposure to harsh environmental conditions. Recognizing the signs of malfunction early and addressing them can prevent the system from failing completely, which would lead to costly repairs and downtime. Below are some of the most common issues encountered with bus air conditioners and how they can be quickly identified and resolved.

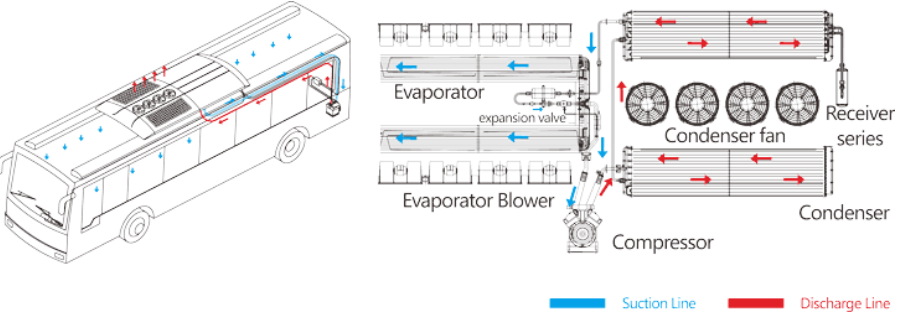

Inconsistent cooling or a complete lack of cooling is one of the most common complaints from bus passengers. The primary causes of this issue include refrigerant leaks, compressor failure, and clogged air filters. Refrigerant leaks can occur due to wear on the system’s components or damage to the refrigerant lines, causing the refrigerant levels to drop and the cooling capacity to diminish. Without sufficient refrigerant, the system cannot cool the air effectively. The compressor is another crucial component, responsible for circulating refrigerant through the system. If the compressor fails, the air conditioner will not be able to cool the air. Another simple cause of poor cooling is clogged air filters, which restrict airflow and prevent the system from efficiently cooling the bus.

Possible Causes of Cooling Issues | Impact on the System | Solutions |

Refrigerant Leaks | Low refrigerant levels reduce cooling | Check for leaks and refill refrigerant |

Compressor Failure | Air conditioner won’t cool effectively | Inspect compressor and replace if needed |

Clogged Air Filters | Restricted airflow, poor cooling | Clean or replace filters |

When faced with inconsistent cooling, the first step is to check the refrigerant levels. If refrigerant is low, the system needs to be recharged, but before refilling, it’s essential to identify and fix the source of the leak. Next, inspect the compressor for signs of malfunction, such as unusual noises or failure to activate. If the compressor is faulty, it will need to be replaced. Lastly, check the air filters. Over time, filters can become clogged with dust, dirt, and debris, restricting airflow. Cleaning or replacing the filters is a simple fix that can restore airflow and improve cooling efficiency.

TCHAIN’s air conditioners are designed to handle a wide range of bus sizes, from small 6-meter buses to larger 14-meter vehicles. Their advanced systems, built with high-quality components, are engineered to minimize issues such as refrigerant leaks and compressor failures. With over 60 types of bus air conditioners developed, TCHAIN ensures that every system is tailored for efficiency and long-term performance. The company’s focus on energy-efficient design helps reduce wear on components, resulting in fewer cooling issues and less maintenance.

Strange noises coming from the air conditioner often indicate internal problems that should be addressed immediately. Common causes of these noises include loose parts, worn-out fan blades, and debris in the vents. Loose components, such as screws or bolts, can cause vibrations that result in rattling or clanking sounds. Worn or damaged fan blades can cause grinding or scraping sounds as they struggle to move air efficiently. Debris, such as leaves or dust, can get trapped in the air intake vents or the fan, obstructing airflow and causing whistling or whirring noises.

If you hear unusual noises, start by checking the fan blades. Look for any signs of wear or misalignment. If the blades are damaged or worn out, they will need to be replaced. Next, inspect the system for any loose parts, such as screws or bolts, and tighten them to prevent vibrations. Lastly, clear any debris or obstructions in the vents or air intake system. A thorough cleaning can eliminate most noise issues and improve airflow.

Unpleasant odors emanating from the air conditioning system can significantly reduce the comfort level of bus passengers. The most common causes of bad odors are mold, bacteria, and clogged drainage tubes. Mold and bacteria thrive in the moist environment of the evaporator coil, particularly when the system has not been used for some time or when the drainage system is clogged. Stagnant water in clogged drainage tubes can also lead to foul smells that circulate throughout the bus when the air conditioner is running.

To eliminate bad odors, it’s important to first clean the evaporator coil. This can be done by carefully removing the coil and cleaning it with a mold and bacteria-killing solution. Next, disinfect the air ducts using appropriate cleaners to remove any lingering bacteria or mold spores. Finally, ensure the drainage system is clear by removing any blockages that could cause water to accumulate. Regular cleaning of the air conditioning system will prevent mold buildup and keep the air fresh inside the bus.

Regular maintenance is key to ensuring that the bus air conditioning system continues to perform efficiently. Cleaning the filters and replacing them periodically helps maintain optimal airflow. Clogged filters restrict airflow, causing the system to work harder and reducing cooling efficiency. Dirty filters can also lead to overheating and premature component failure. Cleaning or replacing filters at least every 3 months (depending on usage) ensures that the system runs smoothly and efficiently.

● Check filters regularly: During routine inspections, check for dirt, dust, and debris buildup in the filters.

● Replace filters if needed: If the filters are damaged or overly clogged, replace them immediately to ensure proper airflow.

● Use high-quality filters: Ensure that replacement filters are of high quality and designed to trap fine particles.

Low refrigerant levels are one of the main reasons for a bus air conditioner’s reduced performance. Over time, refrigerant can leak from the system, resulting in decreased cooling efficiency. As part of regular maintenance, bus operators should check refrigerant levels at least once a year or whenever there are signs of reduced cooling. If the refrigerant level is low, it needs to be refilled, but it is crucial to find and fix any leaks first to prevent the problem from recurring.

TCHAIN’s helium leak detection system and other advanced diagnostic tools ensure that their bus air conditioners are thoroughly tested for potential issues. Regular professional inspections help detect early signs of wear, leaks, or mechanical failure, allowing for preventive maintenance. By working with TCHAIN’s experienced technicians, bus operators can ensure their air conditioning systems stay in optimal working condition, avoiding costly repairs and reducing system downtime.

Electrical issues, such as blown fuses or faulty switches, can prevent the air conditioner from turning on or working properly. Start by checking the fuses and wiring for any visible signs of damage. If the wiring appears intact, test the switches and the thermostat to ensure they are functioning properly.

If the compressor is malfunctioning, check for unusual noises such as grinding or hissing, which can indicate internal damage. If necessary, replace the compressor with a new one. For refrigerant issues, locate any leaks and refill the refrigerant to the manufacturer’s recommended levels. Ensure the system is sealed to prevent future leaks.

Blocked air vents can significantly reduce the effectiveness of the air conditioning system. Ensure that the vents are free of obstructions, such as dirt, debris, or physical objects. Clean the air intake vents regularly, and check the blower motor for functionality. If airflow is still restricted after cleaning, it may be necessary to inspect the internal components for more serious issues.

Rooftop Bus Air Conditioner:The rooftop air conditioner is perfect for larger buses and provides an efficient cooling solution without taking up valuable space inside the bus. These systems are designed to maintain a consistent temperature, even on long trips or during peak usage.

Built-in Bus Air Conditioner:For buses with limited rooftop space, TCHAIN’s built-in air conditioners offer a compact and efficient solution. These units integrate seamlessly with the bus design and provide optimal cooling without compromising space.

Double Decker Bus Air Conditioner:For double-decker buses, TCHAIN’s double-decker air conditioners are designed to ensure even cooling on both floors. The system distributes cool air uniformly across both levels, ensuring that passengers in the upper deck experience the same comfort as those below.

TCHAIN’s electric bus rooftop air conditioners are specifically designed to be energy-efficient, minimizing power consumption while providing excellent cooling performance. These units help extend the operational range of electric buses by reducing the energy demand from the air conditioning system.

TCHAIN continues to innovate in the electric bus air conditioning sector, ensuring that their systems are optimized for energy conservation while maintaining high cooling performance. Their solutions address the specific needs of electric vehicles, including reduced power consumption and enhanced efficiency.

While many issues can be resolved through basic troubleshooting, some problems may require professional attention. If you notice persistent issues despite troubleshooting or hear strange noises that you cannot identify, it is time to call a professional technician. A qualified technician will have the tools and expertise to diagnose complex problems and perform necessary repairs.

TCHAIN offers comprehensive after-sales support through its nationwide network of authorized dealers and service technicians. With nearly 100 authorized service points, TCHAIN ensures that bus operators have access to fast, reliable assistance whenever needed.

Bus air conditioners are vital for maintaining a comfortable and efficient environment for passengers and drivers. By understanding common problems, troubleshooting issues quickly, and performing regular maintenance, bus operators can keep their systems running smoothly and prevent costly repairs.

With over 36 years of expertise, TCHAIN continues to be a leader in bus air conditioning, offering reliable, energy-efficient solutions tailored to meet the needs of bus operators. Their commitment to innovation, quality, and sustainability ensures that their products deliver superior performance and value to customers worldwide.

A: Common problems with a bus air conditioner include inconsistent cooling, strange noises, bad odors, and refrigerant leaks. These issues can be caused by clogged filters, compressor failures, or a lack of maintenance. Regular inspection and quick troubleshooting can help resolve these problems fast.

A: To fix inconsistent cooling, check the refrigerant levels and refill if necessary. Inspect the compressor for any faults and clean or replace clogged air filters. These steps can restore proper cooling and improve efficiency in your bus air conditioner.

A: Strange noises from a bus air conditioner are usually caused by loose parts, worn-out fan blades, or debris in the vents. Tightening loose components, replacing damaged fan blades, and clearing debris can fix the issue and reduce unwanted noises.

A: Filters should be cleaned or replaced every 3 months, depending on usage. Regular maintenance helps prevent airflow restriction and ensures your bus air conditioner works efficiently, improving cooling performance and extending the system’s lifespan.

A: Regular maintenance of a bus air conditioner ensures optimal performance, reduces the risk of breakdowns, and extends the system’s lifespan. By addressing issues early, such as low refrigerant or clogged filters, maintenance helps avoid costly repairs and ensures a comfortable ride for passengers.